Naperville Residents - Learn Lean Six Sigma’s History Here

Contact Us

Before you make any decision about your future, what methodology you should learn, and so on, you will need to do proper research and when you get a list of the options, always go deeper. In the case of Lean Six Sigma, we always encourage individuals and companies to review the information that is not only about how the methodology works but also its history. Thus, whenever you contact Lean Six Sigma Curriculum for Naperville High School Students of Illinois, our team will start by telling you a bit about history. In fact, we will start right below.

Let’s start by stating that Lean Six Sigma is a combination of Japanese management principles and methods, but mainly two methodologies that can be traced back to the USA.

To go in order, the Japanese influence on Lean Six Sigma is Kaizen. It emphasizes cooperation, commitment, and continuous improvement.

LSS is based on the principle of Kaizen, which makes it so valuable. Kaizen is unique in that it emphasizes small, positive changes and reduces the need for unnecessary steps and processes, saving time.

How is it possible that a method has its roots in Japanese works in the USA? Because it mostly addresses the need of American companies to achieve the same that Japanese companies were able to thanks to Kaizen.

LSS was established in 1987 to compete with Japan’s superior products and to adopt Japanese principles to achieve better results.

These principles were developed to reduce waste and take non-value-adding actions. Large U.S. companies adopted them in the 1990s. However, the entire concept of LSS actually comes from two individual methods: Lean and Six Sigma.

How Lean 6 Sigma Originated from Many Methodologies

While Kaizen is the concept’s origin, the method’s inception and construction are based on the last two methodologies mentioned.

It is important to be able to distinguish between Six Sigma and Lean. They are distinct elements that were combined and had aspects in common. However, each element has its own principles and basics for our combined method.

Because of its structure and principles, Lean is often regarded as a way to reduce waste and customer satisfaction. When referring to Toyota, people often refer back to Lean’s origins.

Toyota was involved in the system, which is known as the “Toyota Production System” or TPS. John Krafcik was searching for a name that would describe the TPS system. On a whiteboard, he wrote down the differences and characteristics between Toyota’s system and traditional production and concluded that Toyota’s system requires less of everything in order to create value.

This is how Lean Thinking was created quickly. It is focused on reducing waste and other non-value-added activities.

Lean is built on its own principles and foundations. Understanding the customer is key to understanding each process’ value stream and waste.

On the other hand, Six Sigma is an American-based method with roots dating back to the 1980s. Motorola created six Sigma as the company was having a difficult time being a competitor to foreign companies back then, and its CEO Bob Galvin set the goal of tenfold improvement within five years.

The plan focused on global competitiveness and improving participative management, quality, and productivity; for all this, 6 Sigma ended up being the solution.

Six Sigma quickly became the standard for all Motorola business processes, and every employee was trained.

Six Sigma and Lean, taken together, recognize that change is in the process. Six Sigma complements the Lean approach well and is a great tool for improving every area.

The Kaizen method is still Japanese, but Lean and 6 Sigma were developed in the USA, and thanks to them, LSS was born.

But How Is It Used?

LSS has been used in many different ways throughout history. It’s designed to improve productivity and efficiency and reduce waste.

Understanding the principles and solutions to Lean, Six Sigma, and Kaizen is a great idea. They will allow you to see the entire methodology’s advantages and drawbacks.

Lean helps workers and companies better understand customers and prioritize their needs. To achieve perfection, they can focus on the company’s value stream, processes, and value flow.

Six Sigma is dedicated to excellence and a system that promotes efficiency and clean operations and is committed to continuous improvement and innovation.

Lean Six Sigma is a tool that can be used to benefit students, professionals, and businesses. They will be able:

- Learn how to reduce waste.

- Increase efficiency.

- Reduce errors.

- The company will be less at risk.

- It is possible to improve your time management.

- Lower costs translate into higher revenues and better salaries.

- Get motivated.

- Innovation and leadership are essential.

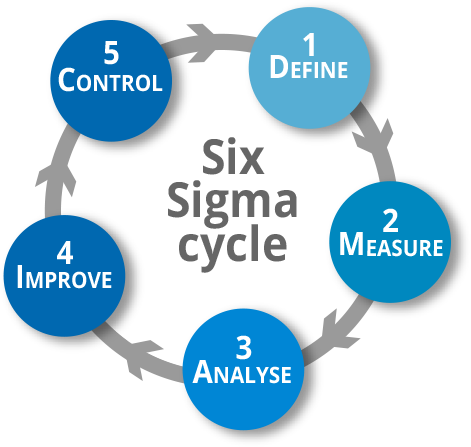

This follows the DMAIC structure for 6 Sigma and the principles surrounding each method.

Of course, the methodology is mostly implemented in companies and businesses originally in manufacturing, but today, more industries benefit from Sigma.

Training & Certification

For all information and certifications, contact our Lean Six Sigma Curriculum Pros of Naperville team to learn more. Your students or employees will be able to join a group of people who are skilled in problem-solving, continuous improvement, and team building.

We know the history and workings of Lean Six Sigma. We are able to teach students in high school, college, and all business professionals.

We want you to enjoy all the benefits, that you are valuable in every place you work and that you add value to American industries.